OUR CORE TECHNOLOGY

Quantum Light Chip

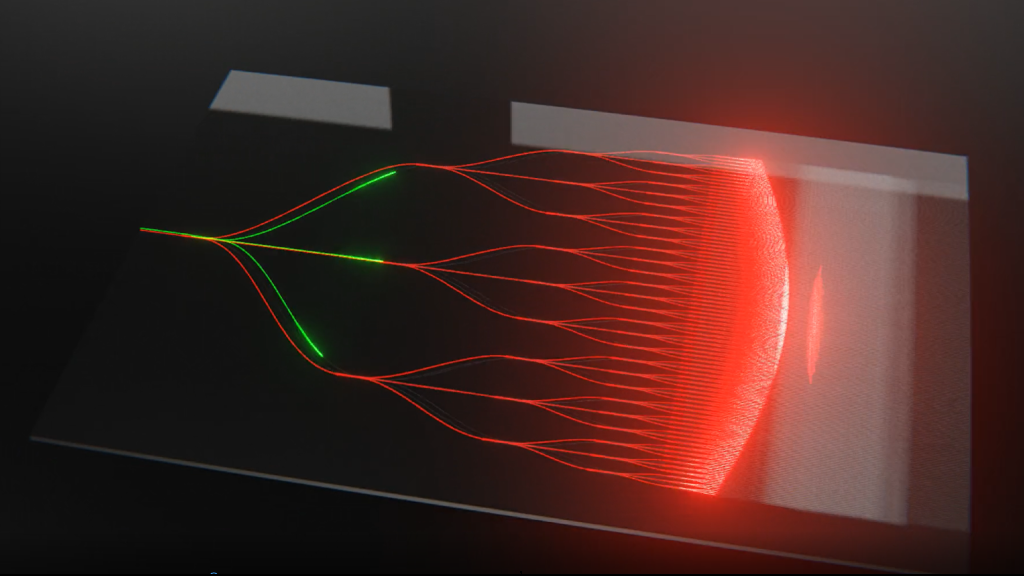

VitreaLab’s core technology is the Quantum Light Chip (QLC), a photonic integrated circuit that allows controlling laser light on the micro-scale. Each chip contains thousands of precisely fabricated low-loss optical waveguides, which are interfaced with nanoimprinted micro-optics to create a uniform and collimated light source.

This light serves as an illumination device for LCoS-based AR projectors for smart glasses or as a backlight for LCD panels in VR displays. Its unique features result in outstanding performance for both applications.

The innovation

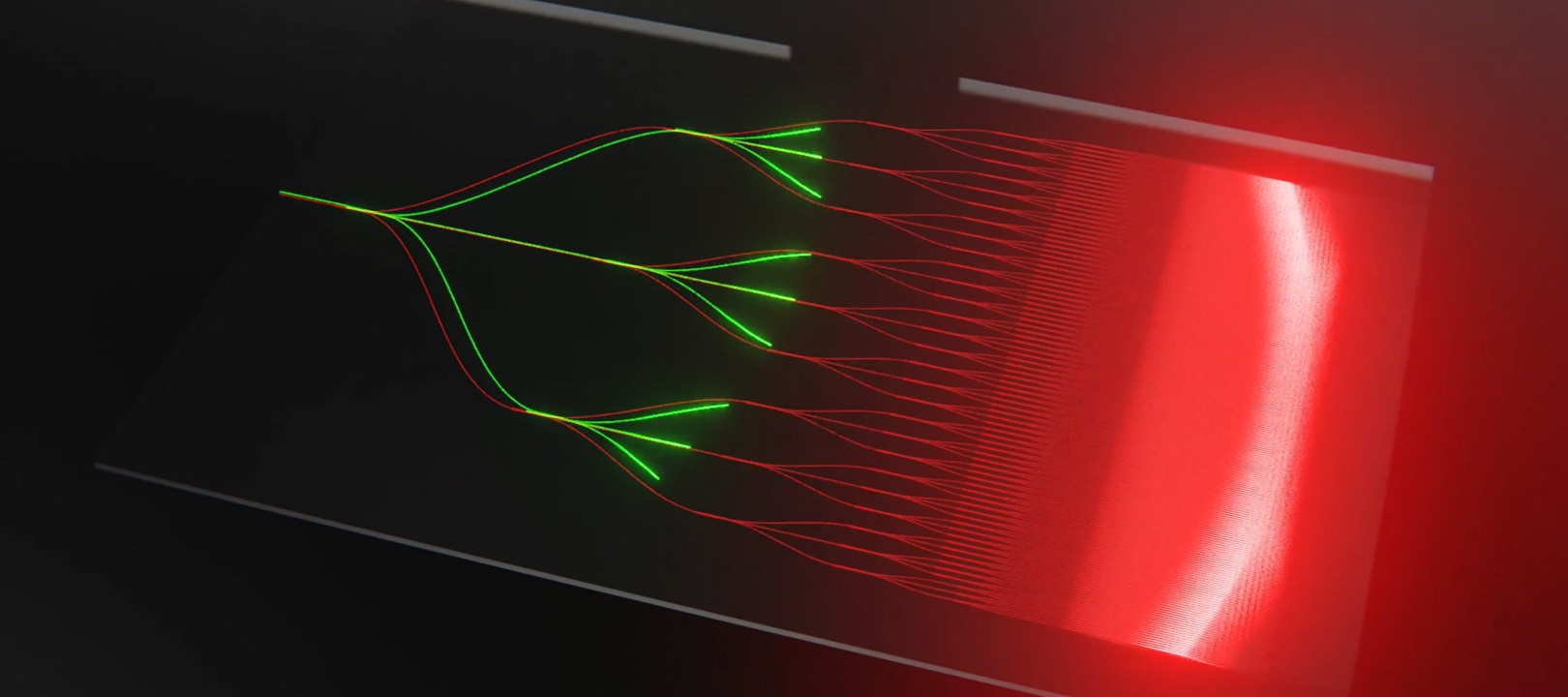

Ultra fine Control of Laser Light

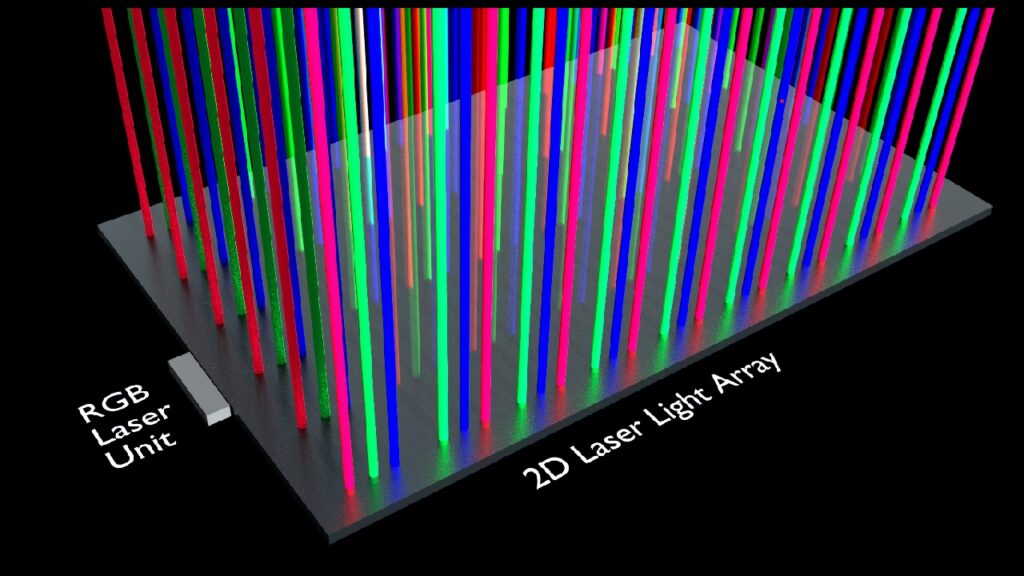

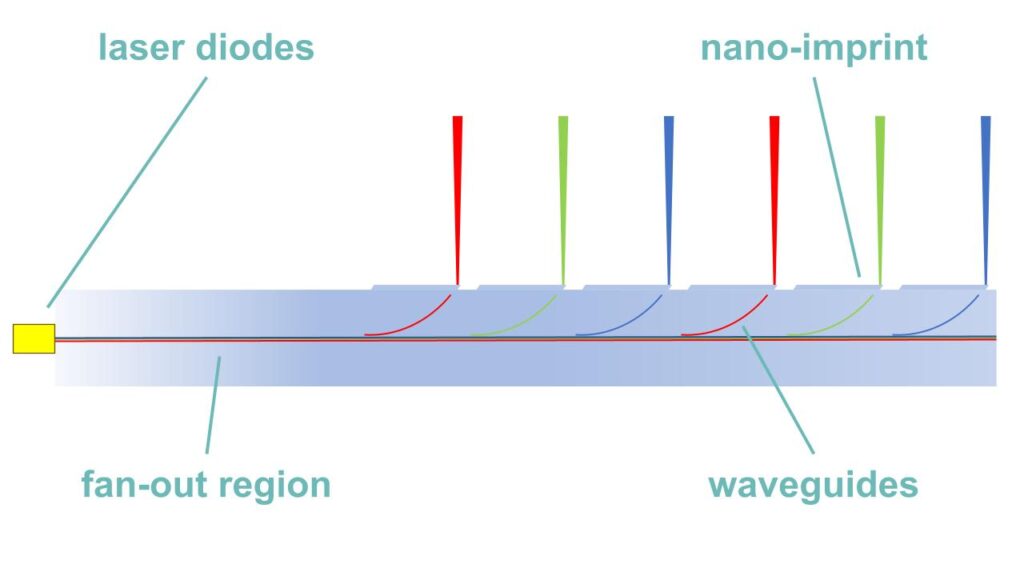

A set of laser diodes, one for each color (red, green and blue), emits polarized laser light. Coupled with the Quantum Light Chip, the laser light is guided through the waveguides inside the Quantum Light Chip. From one input the light is split through a complex network of waveguides ending at the surface of the chip.

Each ending waveguide is aligned to a nanoimprinted micro-optics located at the surface to shape the output beam angle and collimation. Adapting those elements allows us to design the perfect array of laser light for each application.

Laser-Grid illumination

Advantages

✓ BRIGHT

By creating thousands of laser beams out of a single laser diode through a three-dimensional network of waveguides, we provide a very bright illumination.

✓ COLLIMATED

The perfect match of nanoimprinted micro-optics with our waveguides enables us to shape each laser beam individually. Collimation and direction can be customized for specific needs.

✓ POLARIZED

Single-mode laser diodes emit polarized light. The Quantum Light Chip does not affect the polarization. The created laser beam array therefore emits uniformly polarized light.

✓ LOW COST

The Quantum Light Chip can be fabricated in high volumes and at low costs using our proprietary manufacturing process.

✓ EFFICIENT

The high efficiency of laser diodes in combination with the collimation and polarization allows a very efficient use of the emitted light.

✓ COLORFUL

The wavelengths of the laser diodes used make a color gamut of >99% of Rec.2020 possible.

Ready for mass fabrication

Proprietary

Fabrication Process

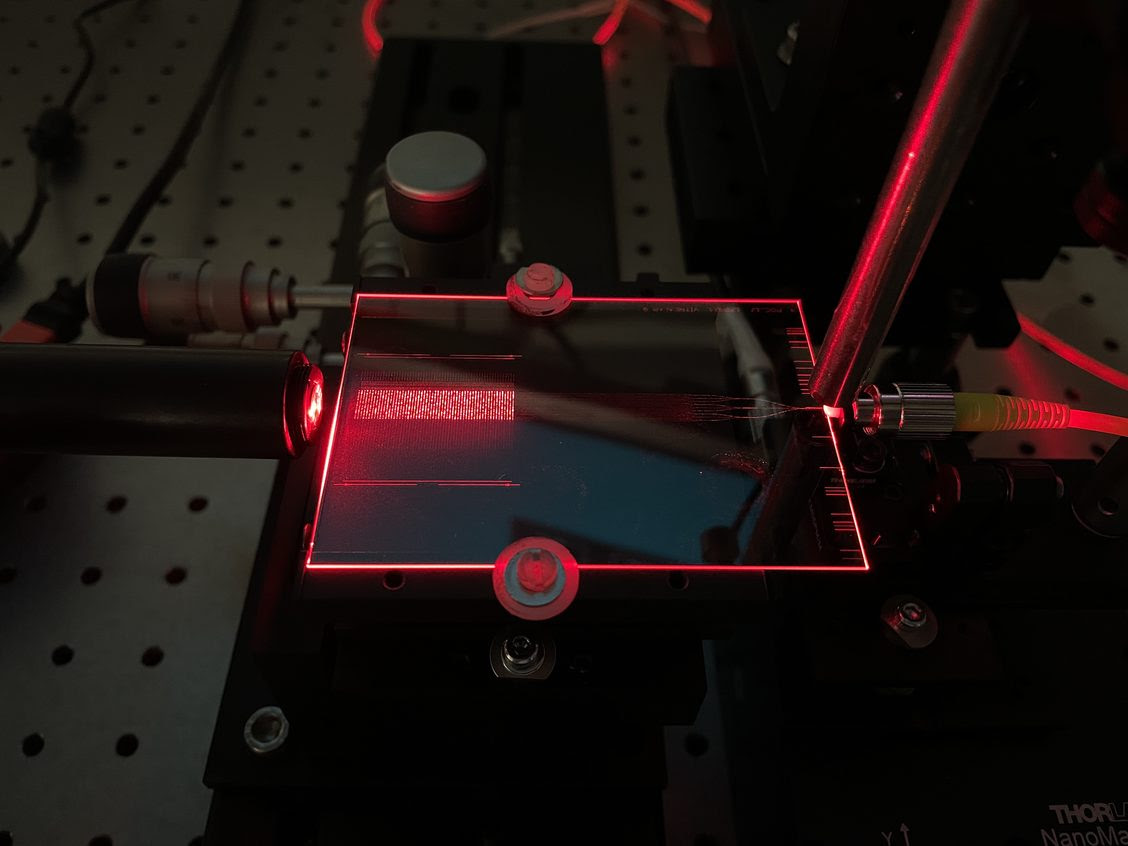

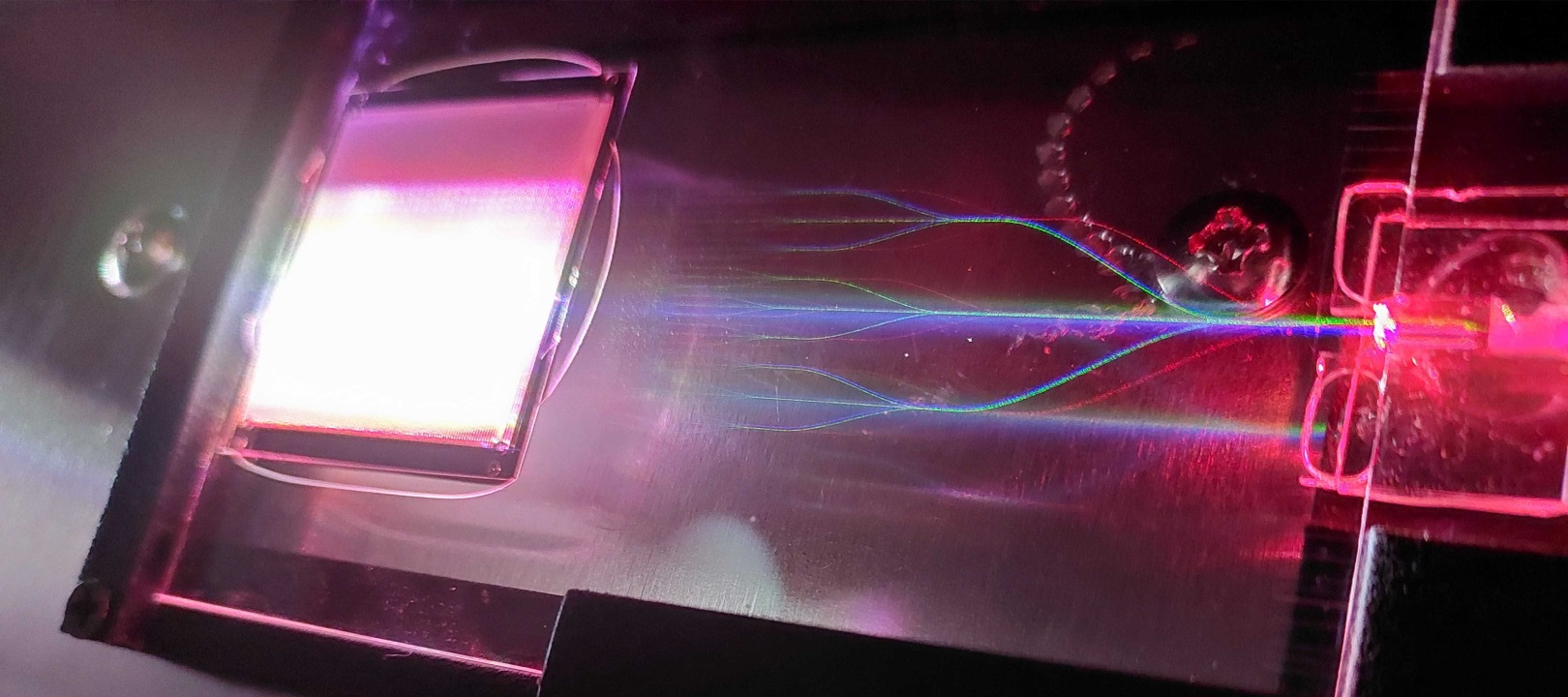

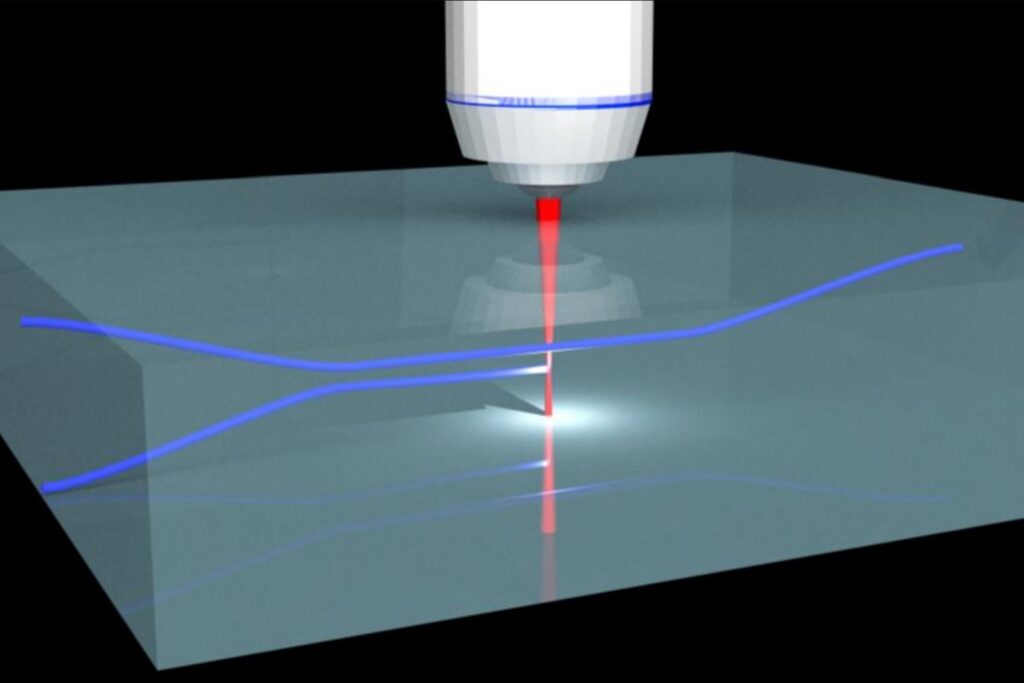

We have developed and patented a fabrication process that allows us to produce a three-dimensional network of waveguides inside a standard display glass.

The waveguides are manufactured by direct laser writing. The chip layout is designed with a highly versatile computer-based tool.

Following the direct laser writing, we add a nano-imprint layer to the Quantum Light Chip surface. This allows us to control the direction and collimation of each laser beam exiting the chip.

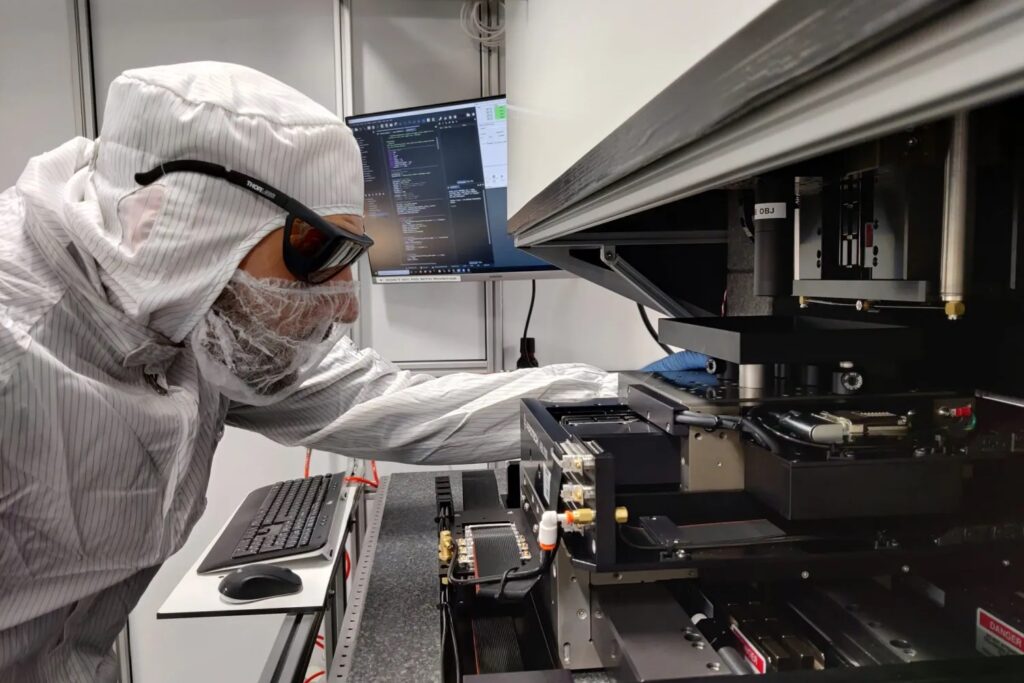

Our lab is equipped with a femtosecond laser system with an extremely accurate wafer positioning system. This system is capable of small series of production. The fabrication process as well as the quality control process are scalable for mass production.

Read more about our production facilities in our blog article:

Wide range of use cases

Applications

Light engines are the key component of smart glasses. Our Quantum Light Chip technology makes them exceptionally bright and efficient.

High dynamic range and low prices can be achieved when combining an LCD panel with our Quantum Light Chip. A perfect match for VR headsets.

HEAD UP DISPLAYS

Larger Quantum Light Chip sizes with several sets of laser diodes are ideal for providing an alternative light source in head-up displays.

OTHERS

Besides the display industry, the Quantum Light Chip can be used for telecommunication or medical devices.